Innoline® 50/50 Four Pipe System Overview

Whalen's Innoline® 50/50 Four Pipe System features all the advantages of a conventional 4-pipe system but reduces pump and piping requirements by 50 percent.

Whalen's Innoline® 50/50 Four Pipe System features all the advantages of a conventional 4-pipe system but reduces pump and piping requirements by 50 percent.

During design day conditions, two pumps – each sized to carry 50 percent of the total flow – operate in parallel to deliver 100 percent of the hot or chilled water required.

Marginal days can be handled by either one or two pumps circulating hot or chilled water through one or both heat-exchangers.

This design also allows pump and motor usage to be staged as conditions require, keeping energy demands at a minimum.

- Benefits

- How It Works

- Technical Data

- Literature

Most buildings run at peak capacity only a few weeks during the year. The Innoline® 50/50 Four Pipe System takes advantage of this fact by using smaller pumps that can be staged to run fewer hours compared to a single larger pump.

Combine this with the operation of only one of the two fans during part of the year, and the energy savings are significant.

The Innoline® 50/50 Four Pipe System is practically maintenance-free, with only the filter requiring periodic replacement or cleaning. There are also no control valves and piping joints that can lead to leaks and service calls.

Lower Installed Costs

The overall system main size is reduced by 50 percent since each side of an Innoline® 50/50 Four Pipe System unit handles one-half of total cooling requirements. This translates into smaller standard pumps and reduced labor times.

By design, each unit is naturally balanced once the flow is established in the riser. The balancing and venting of individual units is a "task of the past." Instead, you gain the benefits of a reverse return balancing system without the need to run an express riser within the building.

Increased Reliability

By designing the Innoline® 50/50 Four Pipe System unit with two equally sized heat exchangers, 50% system redundancy is provided during peak the heating and cooling seasons.

Advantages of Whalen Equipment

- Less floor space required

- Eliminates zone valves and transformers

- Unit-mounted plug-in t-stat factory wiring

- Higher BTU output with lower water temperatures

- Horizontal piping eliminated

- Installation time slashed

- Less maintenance – filter change twice a year … motors permanently lubricated … no zone valve replacement headaches

- No field wiring of transformers, zone valves or t-stats

- No paint touch-up after installation

- Quick venting of system

Advantages for Building Owners

- Reduced operating costs: Each side of the unit can operate independently, yielding energy savings from reduced pumping and fan horse power usage

- A reduction in operating costs, with two fans per unit sized for 50 percent of total CFM required

- Simplified maintenance procedures, thereby reducing costs

- Elimination of all electric valves and flow control valves

- Absence of brazed joints within the cabinet

- Low maintenance – permanently lubricated … no valves … filter change only

- Quiet operation

- 4-pipe control during intermediate seasons

- Design aesthetics – aluminum Grilles and no unsightly steel panels or access openings

Advantages for Contractors

- No unit balancing or reverse return piping

- No venting of individual units

- Supply/return main costs are reduced due to 50% performance capability

- Reduced number of solder joints

- Small riser/drain grouping (10 in. core drill)

- Galvanized cabinet is ideal for direct drywall application – no framing required

- Uniform riser pipe sizing simplifies distribution of units in a building

- Units can be installed early in the construction cycle

- Significant reduction in total installation and operating costs

In the simplest terms, Whalen's Innoline® 50/50 Four Pipe System unit is the combination of two 2-pipe riser fan coil units. Each half of the unit is sized to meet one half of the heating and cooling load.

This unique arrangement allows the system to stage on and off to meet the varying demands each day and throughout the year. The ability provides greater comfort while yielding increased operating savings.

The Innoline® 50/50 System allows design day operating costs to be incurred only when necessary. By using half of the normal main size, with a double Riser Heat Exchanger in each unit, the Innoline® 50/50 System delivers only the load required for each season, substantially reducing installation and operating costs.

The pumps on an Innoline® 50/50 System are up to 50% smaller than those found on a conventional 4-pipe system. Up to 85% of the time a fan coil unit is operating at less than full capacity. The Innoline® 50/50 System allows you to realize significant operational savings during this time.

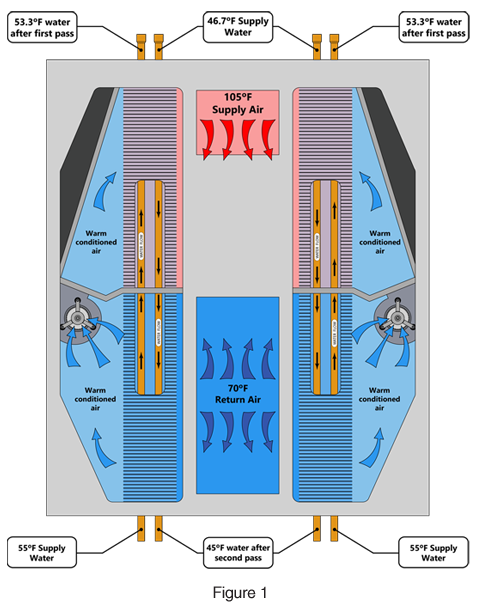

During the winter, when full heating is needed, each half of the system operates in the heating mode, cycling on and off between 0%, 50%, and 100% capacity based on the demand. (see Figure 1)

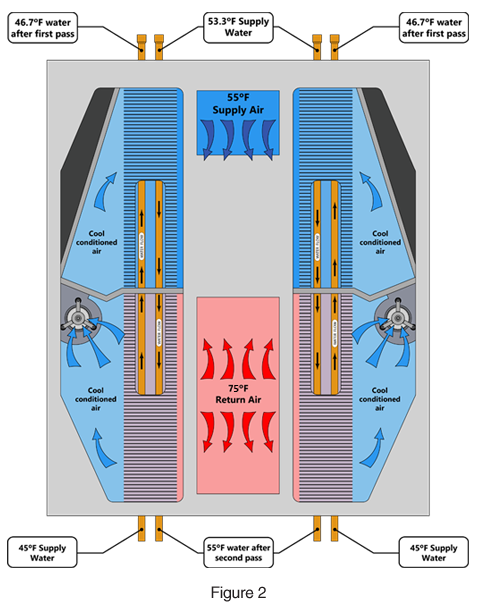

During summer, when full cooling is needed, each half of the system operates in the cooling mode, cycling on and off between 0%, 50%, and 100% capacity based on the demand. (see Figure 2)

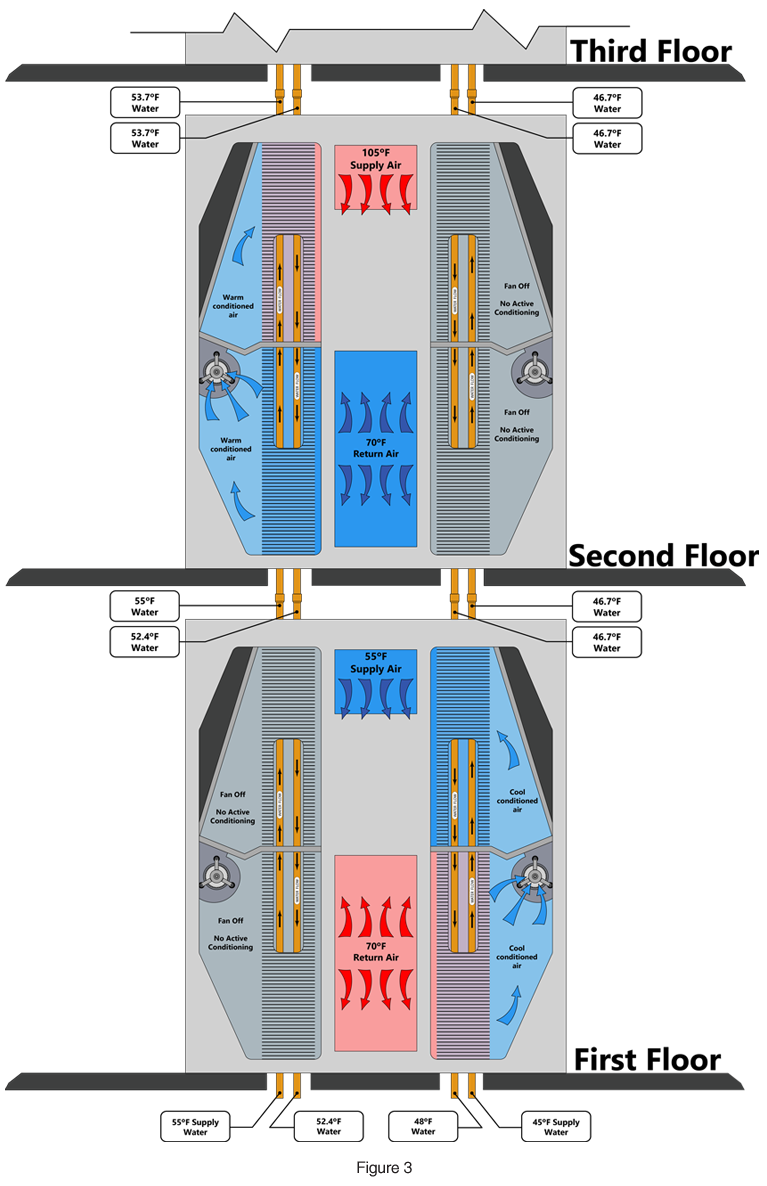

During the spring and fall seasons, when temperatures can fluctuate from day to day, the Innoline® 50/50 system has all the advantages of a 4-pipe system but with the simplicity and energy efficiency of a riser fan coil unit. One unit can operate in cooling mode while another can operate in heating mode based on the needs of each space. No longer are you locked into just heating or just cooling; with the Innoline® 50/50 system you can heat OR cool without the operating expense of a 4-pipe system. (see Figure 3)

The represents the most striking cost difference between a Whalen Innoline® 50/50 Four Pipe System design and a conventional 4-pipe system. Rather than 100% of the chilled and hot water flow being circuited by two pumps rated for 100% of their respective flows, the Innoline® 50/50 Four Pipe System efficiently delivers 4-pipe capacity with just half of the pumping requirement … and the unnecessary full flow requirement during a marginal day during the shoulder seasons is eliminated.

Innoline® 50/50 Four Pipe System

Sales Brochures

![]() Commercial Product Line Brochure

Commercial Product Line Brochure![]() Commercial Product Line Brochure - Fan Coils Only

Commercial Product Line Brochure - Fan Coils Only

![]() Innoline® 50/50 Fan Coil Brochure

Innoline® 50/50 Fan Coil Brochure

Cut Sheets

![]() Innoline® 50/50 Fan Coil Cut Sheet

Innoline® 50/50 Fan Coil Cut Sheet

Design Guides

![]() Innoline® 50/50 Four Pipe System Design Guide

Innoline® 50/50 Four Pipe System Design Guide

Installation and Operation Manual

![]() IOM – Innoline® 50/50 Four Pipe Riser Fan Coil

IOM – Innoline® 50/50 Four Pipe Riser Fan Coil

Product Specifications

![]() Unit Specification – Innoline® 50/50 Four Pipe Riser Fan Coil

Unit Specification – Innoline® 50/50 Four Pipe Riser Fan Coil

Drawing Files

![]() Revit® Drawing – Innoline® 50/50 Four Pipe Riser Fan Coil

Revit® Drawing – Innoline® 50/50 Four Pipe Riser Fan Coil